Product features

☆ Compressed air is equipped with air purification and drying equipment. Clean and dry air ensures the prolonged use of the molecular sieve.

☆ Rational structural design enhances the adsorption efficiency of the molecular sieve, and a special airflow diffusion device prevents molecular sieve pulverization caused by high-speed flow impact.

☆ The equipment is compact, occupying a small footprint. A PSA nitrogen production system can be installed on the same base, creating an integrated structure.

☆ PLC control technology is utilized, adjustable based on nitrogen purity, and a reserved interface allows for remote computer control.

☆ The internally balanced automatic tightening system with nationally patented technology and unique molecular sieve filling technique enhances the long-term operational reliability of the entire unit.

Working Principle

The YN series nitrogen generator operates based on the principle of pressure swing adsorption, utilizing high-quality carbon molecular sieves as the adsorbent to produce nitrogen gas from the air at a certain pressure. Compressed air, purified and dried, undergoes pressure swing adsorption within the adsorber. Due to aerodynamic effects, oxygen diffuses through the micropores of the carbon molecular sieve at a significantly faster rate than nitrogen. As a result, oxygen is preferentially adsorbed by the carbon molecular sieve, while nitrogen is enriched in the gas phase, forming the final nitrogen product. Subsequently, the pressure is reduced to atmospheric pressure, allowing the adsorbent to desorb impurities such as oxygen, achieving regeneration. Typically, the system includes two adsorption towers: one tower adsorbs to produce nitrogen, while the other tower desorbs to regenerate. PLC program controllers control the opening and closing of pneumatic valves, facilitating alternating cycles between Product features the two towers to achieve continuous production of high-quality nitrogen gas.

Note:

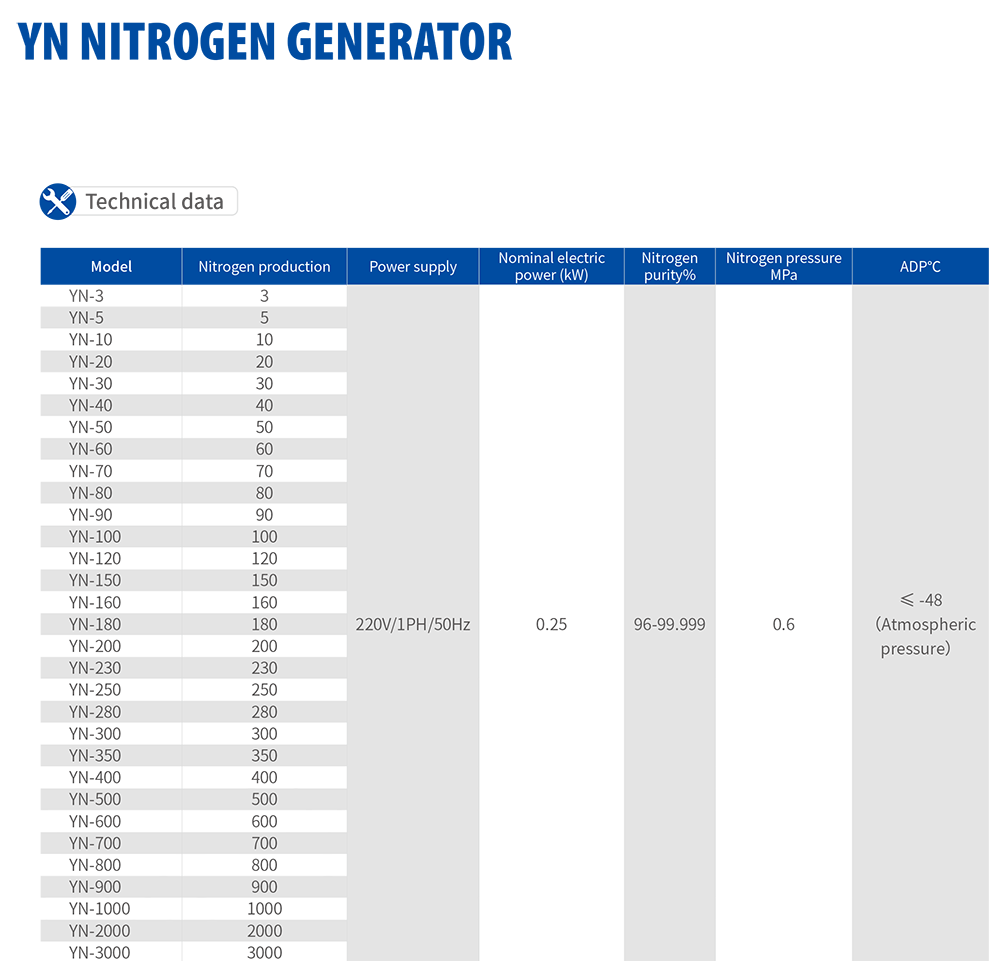

☆ Model designation explanation: Type A - Purity 96%,Type B - 98%, Type C - 99%. Standard Type - 99.5%, Type D -99.9%. Type E - 99.99%, Type G - 99.999%.

☆ Type D nitrogen generators are available in capacities ranging from 3 to 1200 Nm³/h, Type E ammonia generators can be chosen within 3-600 Nm³/h, and Type G nitrogen generators can be selected within 3-100 Nm³/h.

☆ Data for nitrogen purity within 99.9% is based on raw compressed air at 0.8 MPa (gauge pressure), 20° C ambient temperature, 0-meter elevation, and 80% relative humidity as the design reference.

☆ Data for nitrogen purity above 99.99% is based on raw compressed air at 0.9 MPa (gauge pressure), 20° C ambient temperature, 0-meter elevation, and 80% relative humidity as the design reference.

☆ When selecting an air compressor, users should consider the difference between the compressor's volume flow rate and the actual discharge, as well as the influence of ambient temperature and humidity on the air compressor's exhaust.

☆ For nitrogen gas with pressures above 0.8 MPa and a dew point of ≤ -48° C, special designs are available.

☆ When placing an order, indicate whether a cabinet-type machine or non-cabinet-type machine is required in the contract.

☆ If there are any changes to the data, the information provided later will prevail.

+86 0757 86418910

No.8, Shapu Road, Shapu Village,Xiaotang,Shishan town, Nanhai District, Foshan City,Guangdong Provice, P.R. China

COPYRIGHT© Foshan tiandiyuanyi purification equipment co.,LTD Copyright 粤ICP备10221385 技术支持:思域科技